SHIPPING INFORMATION

Pinnacle Aircraft Engine will arrange for and manage round trip shipping logistics from and to anywhere in the contiguous United States for Pinnacle Aircraft Engine overhauled engines at no charge to Pinnacle Aircraft Engine's customer. Charges not covered by Pinnacle Aircraft Engine may include: expedited shipments, shipment of an empty crate, and additional carrier services such as lift-gates, inside delivery, etc.

Pinnacle Aircraft Engine will not reimburse for unauthorized freight charges.

The customer is responsible for all other shipping costs for parts, inspection services, warranty, and repair services, etc.

For Lycoming and Continental Factory engines, the customer is responsible for shipping to and from the appropriate factory. Pinnacle Aircraft Engine will arrange for and provide customers with a shipping quote using our trusted and economical vendors.

ENGINE CORE RETURN CHECKLIST

Click for PDF version

ENGINE RETURN CHECKLIST

SEND THE ENGINE AS REMOVED FROM AIRCRAFT WITH ALL ACCESSORIES AND COMPONENTS STILL BOLTED IN PLACE

Remove dipstick and dipstick tube from engine and strap to the top of the engine.

Secure all bolt-ons such as ring gear support, fuel unit (carb or injector), and turbo intake systems. Box separately or fasten to pallet securely.

Include lifting eyes, fuel unit arms, magnetos, fittings, lines.

Leave intact all gears required for the engine to run.

Leave internal cylinder baffling in place between the cylinders

DO NOT SEND

Do not ship the engine on tires.

Do not send engine baffling. (send internal cylinder baffling only).

Do not send airframe pieces. (No air boxes or engine frames.....). Missing or damaged airframe pieces are not the responsibility of Pinnacle Aircraft Engine.

Do not send prop governor.

Do not send primer systems.

Do not send engine pre-heaters.

Do not send alternator/generator.

Do not send starter, unless part of engine (Continental).

For questions or concerns, please contact: [email protected]

DEPOSIT DEDUCTIONS COULD BE ASSESSED FOR BROKEN OR MISSING ITEMS DUE TO POOR PACKAGING.

TO AVOID DEDUCTIONS OR ADDED CHARGES ENGINES NEED TO BE SECURE AND PROTECTED.

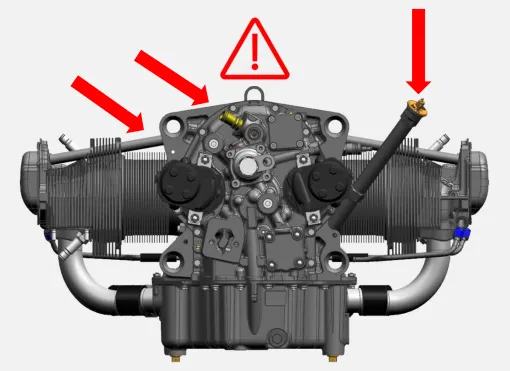

FREQUENTLY BROKEN ITEMS:

DIPSTICK AND TUBE, ROCKER COVERS, RING GEAR SUPPORTS, OIL SUMPS, ENTIRE ENGINES

FREQUENTLY MISSING ITEMS:

LOGBOOKS, LIFTING HOOKS, FITTINGS, RING GEAR SUPPORTS FUEL UNITS & LEVERS, GOVERNOR LINES

ENGINE CORE RETURN CHECKLIST

Click for PDF version

ENGINE CORE PROCESSING

Your engine core is not only of value to you in the form of a deposit, it’s of value to us to be able to overhaul to new specifications for another customer. Often, we are asked about core deposit refund time frames.

Here are some insights into the process of your returned engine core. Once we receive it off the truck, it is visually inspected for missing components and to ensure that the engine is in as removed condition. Commonly missed items to name a few are logbooks, flywheel/ring gear supports, breather fittings, dipsticks, inter-cylinder cooling baffles, accessories and carburetor throttle and mixture arms. It is also looked for damages. Often dipstick tubes are not removed and broken. These need to be removed to prevent this.

The engine is then moved inline to disassemble and inspect. The same department that processes customer engines for overhaul, also disassembles core engines.

Once disassembled, our primary focus for core deposit refund is the inspection of the crankshaft and crankcase and if they meet spec to be safely and legally reused in future engine builds. We hold to specifications outlined by the manufacturers and the FAA which can include checking for cracks, pitting in the crankshaft, bearing journals under serviceable size, bent crankshafts, or bent prop flanges. Crankcases are checked for cracks and wear in common places and if they can be repaired for future engines without risk.

If the crankshaft needs repair after inspection, it requires the crankshaft to be sent to an FAA certified machine shop that specializes in aircraft crankshafts. This is an effort to retain a viable crankshaft from your engine for future builds and to get you full deposit refund. Risks of the machining process can be material removal required is beyond limits, a poor reaction in the plating or hardening processes, warpage in the repair process. These things are rare but are risks to the value. If a crankshaft needs to be sent out, the current turnaround time can be 9 to 13 weeks after our inspection.

If the crankcase needs work after inspection, we do this work in our own facility. Cases go through a 30-point check list. At times crankcases need welding for stress fractures. We also correct any flaws in bore alignment to name a few. Any repair to a case risks warpage or a loss in strength. Again, this is an effort to retain a viable crankcase from your engine for future builds and to get you full deposit refund.

If both crankcase and crankshaft are verified good for future builds, core deposit refund is then issued. The process is not a quick pass-through process. We want to assure customers like you receive not only your deposit refund, we want to assure customers get the best Pinnacle engine possible.

© 2025 Pinnacle AirCraft Engines. All Rights Reserved.