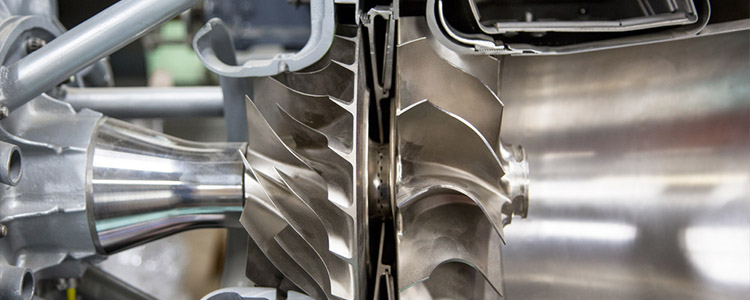

Maintenance on a turbocharger is critical to obtain a long and hassle-free service life. A turbocharger must regularly withstand extreme operating conditions –with exhaust inlet temperatures exceeding 1600° F and the turbine wheel rotating at over 90,000 RPM. Turbine and compression wheel blades must be carefully inspected for any cracks or damage caused by foreign object debris. It is also important to turn the wheels by hand and inspect for any drag or rubbing against the housing. One of the most important processes in the turbocharger is the lubrication system, which is provided by the aircraft engine oil. Oil contamination, foreign object debris, and oil supply problems are the most frequent reasons for premature turbocharger failure and can lead to overheating of the bearings and the center housing.

Request A Quote

Get a FREE no-obligation quote today!

- Whether you need to purchase a new aircraft turbocharger, waste gate, controller or relief valve or want us to rebuild your own parts, you can rely on our 90 years of aircraft turbocharger system component repair experience at Pinnacle Aircraft Engines.

- During overhaul of turbocharger system components, Pinnacle Aircraft Engines technicians carefully inspect all steel and aluminum materials. Turbocharger components are precision built, balanced and pressure tested by Pinnacle’s highly skilled ASE certified master machinists assuring the highest quality in component overhaul services.